Summary Overview

LLDPE (Linear low-density polyethylene) Market Overview:

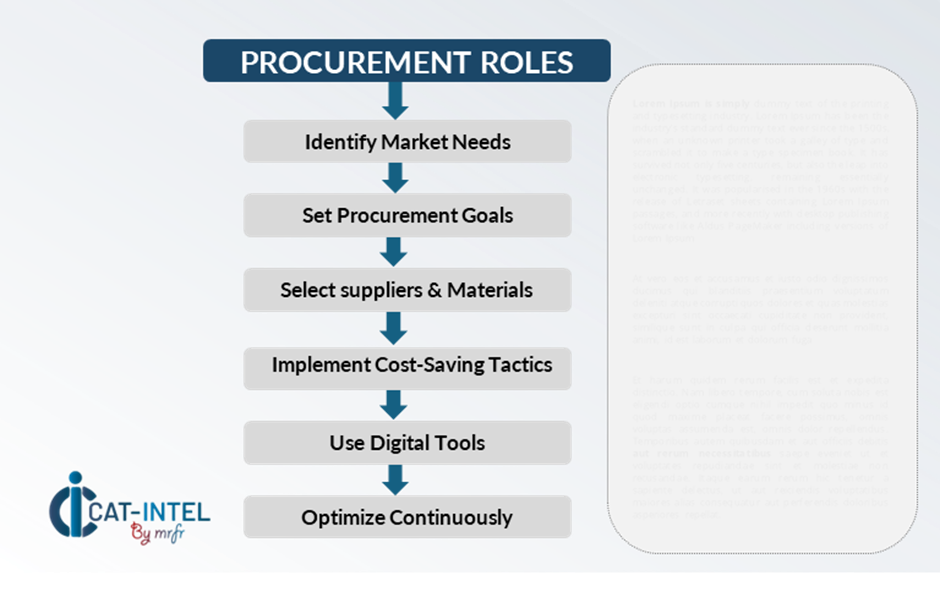

The global LLDPE (Linear Low-Density Polyethylene) market is steadily expanding, driven by increasing demand in a range of industries such as packaging, automotive, construction, and consumer products. This market covers a wide range of LLDPE products, including film-grade, injection molding, and blow molding. Our paper provides a thorough examination of procurement trends, with a special emphasis on cost-cutting initiatives and the growing reliance on digital tools to enhance procurement and manufacturing processes.

Moving forward, key procurement concerns include managing material costs, assuring product consistency, preserving supply chain security, and integrating LLDPE systems into existing production workflows. The use of digital procurement technologies and strategic sourcing is crucial for speeding up LLDPE adoption, improving operational skills, and sustaining long-term competitiveness.

Market Size: The global LLDPE (Linear low-density polyethylene) market is projected to reach USD 123.86 billion by 2035, growing at a CAGR of approximately 5.4% from 2025 to 2035.

Growth Rate: 5.4%

-

Sector Contributions: Growth in the market is driven by: -

Manufacturing and Supply Chain Optimization: There is an increasing demand for real-time data and process integration to improve operational efficiency and streamline the LLDPE production process. -

Growth in Packaging and Industrial Applications: LLDPE is becoming more popular in packaging, flexible containers, and industrial applications due to its strength, flexibility, and low cost. -

Technological Advancements: Advances in polymer production technology, including as automation and AI, are improving the quality and functionality of LLDPE. -

Sustainability Push: To meet environmental and regulatory standards, manufacturers are focused on recyclable and biodegradable LLDPE alternatives. -

Cost Efficiency: LLDPE's ability to provide high-performance qualities at a cheaper cost than alternatives are driving its widespread adoption, particularly in the packaging, agriculture, and automotive sectors.

-

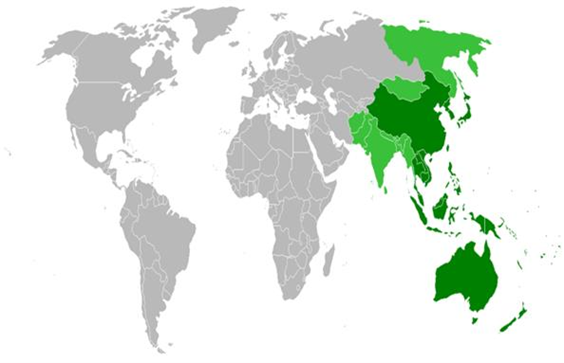

Regional Insights: Asia-Pacific and North America are important production hubs, propelled by cheap production costs and high demand.

Key Trends and Sustainability Outlook:

-

Digital Transformation: The growing use of digital tools and technology in LLDPE production, such as real-time monitoring and predictive maintenance, is increasing productivity while decreasing costs. -

Demand for Lightweight and Flexible Materials: As industries prioritize lightweight materials, LLDPE's flexibility and durability are highly valued for lowering overall material costs while increasing end-product performance. -

Globalization and Expansion: As global trade grows, LLDPE systems must be able to meet a wide range of regional and regulatory regulations, as well as multi-language and multi-currency operational requirements. -

Sustainability Focus: Growing environmental consciousness is driving wider adoption of recyclable LLDPE in areas such as packaging, construction, and agriculture. -

Cloud-Based Solutions in Manufacturing: Companies are using cloud technology to optimize LLDPE production, save infrastructure costs, and improve remote access to operational data.

Growth Drivers:

-

Scalability Requirements: Scalable solutions allow organizations to reduce costs as output increases, resulting in improved economies of scale.

-

Regulatory Compliance: Adherence to regulations governing carbon emissions in manufacturing processes, particularly in energy-intensive industries. -

Advanced Features: The use of modern technologies such as artificial intelligence (AI), the Internet of Things (IoT), and blockchain is improving LLDPE manufacturing capacities by allowing for higher automation, real-time monitoring, and transparent decision-making. -

Customization: There is a growing demand for LLDPE solutions that are suited to individual industries' performance, regulatory, and environmental requirements. -

Data-Driven Insights: Market companies use advanced analytics to estimate material demand, optimize manufacturing lines, and track key performance indicators (KPIs), which helps them stay competitive.

Overview of Market Intelligence Services for the LLDPE (Linear low-density polyethylene) Marke

Recent investigations have identified critical problems in the LLDPE market, including increased raw material costs, supply chain volatility, and the requirement for material performance customisation. Market intelligence studies give actionable insights that can help businesses optimize procurement strategies, cut operating costs, and improve supply chain management efficiency. These insights also help to comply with environmental requirements, assure constant material quality, and successfully manage fluctuating manufacturing costs.

Procurement Intelligence for LLDPE (Linear low-density polyethylene): Category Management and Strategic Sourcing

To remain competitive in the LLDPE market, organizations are fine-tuning their procurement procedures through expenditure analysis and supplier performance monitoring. Effective category management and strategic sourcing are critical to lowering procurement costs while maintaining a consistent supply of high-quality LLDPE materials. Companies that use actionable market intelligence can fine-tune their procurement strategy, optimize supplier relationships, and negotiate advantageous pricing for their LLDPE supply requirements.

Pricing Outlook for LLDPE (Linear low-density polyethylene): Spend Analysis

The pricing outlook for LLDPE is likely to be moderately dynamic, with potential variations caused by a variety of variables. Raw material costs, advances in polymer technology, regional supply chain dynamics, and the demand for sustainable solutions are all important factors to consider.

Graph shows general upward trend pricing for LLDPE (Linear low-density polyethylene) and growing demand. However, there may be fluctuations influenced by economic conditions, technological advancements, and competitive dynamic.

Efforts to optimize procurement procedures, improve supplier management, and implement customized LLDPE solutions are critical for managing material prices. Using digital tools for market monitoring, pricing forecasting using advanced analytics, and effective contract administration can considerably reduce costs.

Despite challenges such as fluctuating raw material prices and changing regulatory requirements, focusing on scalability in manufacturing processes, improving supply chain transparency, and using sustainable, recyclable LLDPE variants will be critical in maintaining cost-effectiveness and operational excellence.

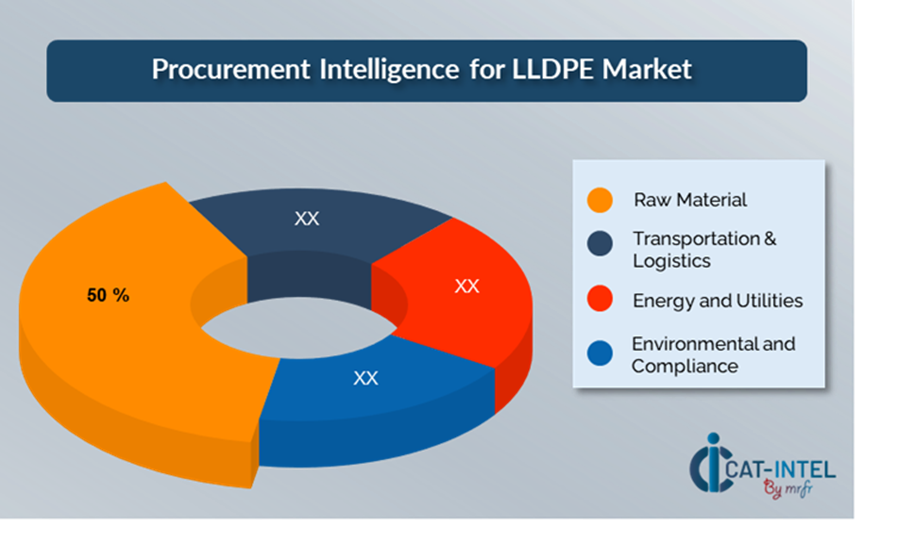

Cost Breakdown for LLDPE (Linear low-density polyethylene): Total Cost of Ownership (TCO) and Cost-Saving Opportunities

- Raw Material: (50%)

-

Description: These expenses are determined by the price of ethylene (the primary feedstock for LLDPE), which fluctuates with crude oil pricing and natural gas availability. -

Trend: Raw material costs may stabilize or climb as sustainable and bio-based materials become more prevalent, depending on whether eco-friendly alternatives are adopted.

- Transportation & Logistics: (XX%)

- Energy and Utilities: (XX%)

- Environmental and Compliance: (XX%)

Cost-Saving Opportunities: Negotiation Levers and Purchasing Negotiation Strategies

In the LLDPE industry, streamlining procurement processes and using strategic negotiation strategies can result in significant cost savings and increased operational efficiency. Establishing long-term agreements with dependable LLDPE suppliers, especially those offering sustainable and recycled material solutions, can result in improved pricing structures and beneficial terms, such as volume-based discounts, bulk purchase offers and service packages.

Partnering with LLDPE providers who value innovation and scalability provides substantial advantages. Suppliers who use cutting-edge technology, such as sophisticated polymerization techniques or sustainable manufacturing methods, allow organizations to access higher-quality resources, increase product performance, and lower long-term operational costs. Implementing digital technologies for LLDPE procurement, such as contract management systems, use analytics, and market monitoring tools, increases transparency, reduces over-provisioning, and maximizes material consumption.

Supply and Demand Overview for LLDPE (Linear low-density polyethylene): Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The LLDPE market is steadily expanding, driven by increased demand in industries such as packaging, automotive, agricultural, and construction. Advancements in production methods, regulatory restrictions, and changing industrial needs all have an impact on supply and demand in the LLDPE sector.

Demand Factors:

-

Sustainability & Environmental Initiatives: LLDPE is in high demand due to the increased desire for sustainable materials and environmentally friendly packaging solutions. -

Adoption of Recycled Materials: A considerable movement toward using recycled LLDPE in production is driving up demand, notably in the packaging and agriculture sectors, where sustainability is a top issue. -

Industry-Specific Needs: Industries including as automotive and construction demand LLDPE variations with specific performance characteristics, such as durability, flexibility, and environmental resistance. -

Technological Integration: The increasing need for innovative LLDPE products that can combine with smart packaging solutions is driving innovation in material development and increasing the demand for sophisticated polymer solutions.

Supply Factors:

-

Technological Advances in Polymerization: Innovations in polymer production technology, such as biodegradable LLDPE variations, are expanding product offerings and boosting supplier rivalry. -

Vendor Ecosystem: The LLDPE industry is getting more varied, with both global chemical giants and niche providers providing specialized solutions. -

Global Economic Factors: Variations in raw material costs, trade tariffs, exchange rates, and regional economic situations can all have an impact on LLDPE prices and availability. -

Customization and Flexibility: Modern LLDPE systems are becoming more modular and adaptable, allowing suppliers to serve enterprises of all sizes and industries.

Regional Demand-Supply Outlook: LLDPE (Linear low-density polyethylene)

The Image shows growing demand for LLDPE (Linear low-density polyethylene) in both Asia Pacific and North America, with potential price increases and increased Competition.

Asia Pacific: Dominance in the LLDPE (Linear low-density polyethylene) Market

Asia Pacific, particularly Southeast Asia, is a dominant force in the global LLDPE (Linear low-density polyethylene) market due to several key factors:

-

Growing Industrial Base: Demand for LLDPE is being driven by the increase of industrial activities, particularly in the packaging, automotive, construction, and electronics industries -

Rapid Infrastructure Development: The Asia-Pacific region is rapidly urbanizing, resulting in a major increase in infrastructure projects such as residential, commercial, and industrial constructions. -

Significant Packaging Industry Growth: Asia-Pacific has a rapidly growing consumer products market. As disposable incomes rise and the retail industry thrives, the demand for flexible packaging materials grows. -

Access to Raw Materials. The Asia-Pacific area has a competitive advantage because to its abundant raw materials and low production costs. Asia-Pacific is a major participant in the LLDPE market due to its low labour costs and large-scale production capabilities. -

Growing Focus on Sustainability: Government incentives and regulatory frameworks fostering circular economy practices are encouraging enterprises to invest in sustainable polymer solutions, cementing the region's position as a significant market.

Asia Pacific Remains a key hub LLDPE (Linear low-density polyethylene) Price Drivers Innovation and Growth.

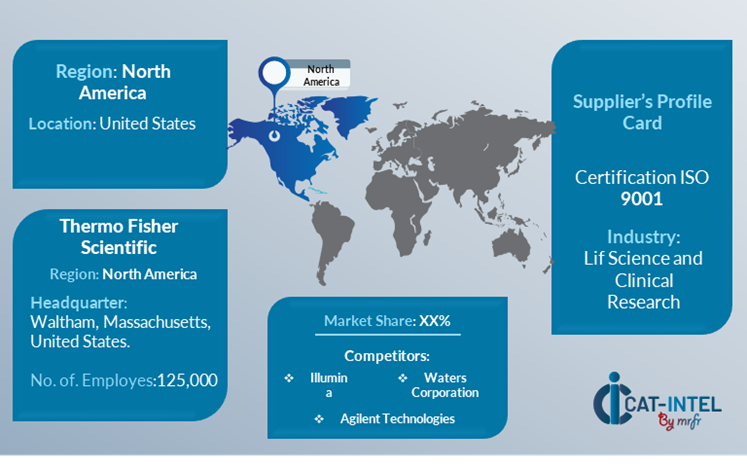

Supplier Landscape: Supplier Negotiations and Strategies

The LLDPE supplier landscape is diverse and highly competitive, with a mix of global industry titans and regional players. These vendors play a crucial role in deciding important considerations include pricing structures, product customization, and service quality. Established chemical giants dominate the market, offering a diverse range of high-performance LLDPE solutions, while smaller, specialized suppliers focus on specific industry applications or product attributes, such as sustainable materials and recyclable LLDPE versions.

The LLDPE supplier ecosystem spans important regions, with both global vendors and local companies catering to unique industry demands. Suppliers are responding to the increased need for sustainability, cost effectiveness, and personalization by developing new production technologies and incorporating cutting-edge solutions. As the industry evolves, companies who value innovative partnerships, sustainable materials, and flexible sourcing strategies will be better positioned to prosper in the increasingly competitive LLDPE market.

Key Suppliers in the LLDPE (Linear low-density polyethylene) Market Include:

- Reliance Industries

- ExxonMobil Chemical

- Dow Chemical

- LyondellBasell Industries

- SABIC

- INEOS

- Chevron Phillips Chemical

- Braskem

- Formosa Plastic Corporation

- China National Petroleum Corporation (CNPC)

Key Developments Procurement Category Significant Development:

Significant Development |

Description |

Market Growth |

The LLDPE market is expanding rapidly because to increased demand in industries such as packaging, automotive, and construction, especially in emerging regions. There is a growing demand for high-performance polymers. |

Cloud Adoption |

The demand for recyclable and bio-based materials in the packaging, agriculture, and consumer products industries is driving providers to innovate and supply recycled LLDPE alternatives. |

Product Innovation |

LLDPE manufacturers are increasing their product offers with sophisticated polymer solutions, including high-strength, flexible variations, biodegradable choices, and smart polymers for industries. |

Technological Advancements |

Advanced extrusion techniques, polymerization methods, and recycling technologies are improving LLDPE's performance, consistency, and cost-effectiveness. |

Global Trade Dynamics |

Changes in trade legislation, tariffs, and environmental policies have an impact on LLDPE market trends. New compliance criteria, particularly those pertaining to plastic waste management and recycling quotas, are influencing manufacturing tactics and price. |

Customization Trends |

Companies are looking for modular solutions and specialty grades of LLDPE that have specific performance properties like flexibility, chemical resistance, and UV stability. |

|

LLDPE (Linear low-density polyethylene) Attribute/Metric |

Details |

Market Sizing |

The global LLDPE (Linear low-density polyethylene) market is projected to reach USD 123.86 billion by 2035, growing at a CAGR of approximately 5.4% from 2025 to 2035. |

LLDPE Technology Adoption Rate |

Around 70% of manufacturers worldwide use LLDPE for a variety of applications, with a major movement toward sustainable and recyclable LLDPE materials in response to environmental requirements.

|

Top LLDPE Industry Strategies for 2025 |

The LLDPE market's key strategies include improving recycling capabilities, incorporating biodegradable versions, prioritizing sustainability in product offerings, and developing tailored LLDPE solutions for niche sectors.

|

LLDPE Process Automation |

To boost operational efficiency, over half of LLDPE producers are automating operations like polymerization, extrusion, and recycling to enhance operational efficiency, product consistency, and cost-effectiveness.

|

LLDPE Process Challenges |

Major hurdles in the LLDPE market include variable raw material costs, recycling process complexity, trade and tariff concerns, and the need to comply with severe environmental standards.

|

Key Suppliers |

Leading LLDPE suppliers include Reliance Industries, ExxonMobil Chemical and Dow Chemical, which provide a wide range of solutions across multiple industries.

|

Key Regions Covered |

Asia Pacific, North America and Europe are key regions for LLDPE adoption, with substantial demand in the packaging, automotive, agriculture, and construction sectors.

|

Market Drivers and Trends |

Sustainability initiatives, the transition to recyclable and eco-friendly materials, growing acceptance of bio-based and recycled LLDPE, and the incorporation of innovative polymer technologies to meet regulatory and performance requirements are all driving growth.

|