Summary Overview

Hydrogen Peroxide Market Overview

The global hydrogen peroxide market is steadily expanding, driven by demand from key industries including pulp and paper, textiles, food and beverage, healthcare, and environmental applications. This market contains many grades of hydrogen peroxide, including as industrial, food-grade, and specialized formulations, each catering to a unique demand in these industries. Our paper delves deeply into procurement trends, with an emphasis on cost-cutting techniques and the use of digital technology to streamline manufacturing and distribution operations.

Key challenges in hydrogen peroxide procurement include managing variable raw material prices, establishing consistent supply chains, maintaining product quality, and dealing with environmental and regulatory issues. The use of advanced procurement techniques and strategic sourcing approaches is crucial for maximizing hydrogen peroxide supply and maintaining long-term sustainability. As global demand rises, organizations are using market data to improve operational efficiency, reduce risks, and remain competitive in a quickly changing market scenario.

Market Size: The global Hydrogen Peroxide market is projected to reach USD 5.43 billion by 2035, growing at a CAGR of approximately 4.85% from 2025 to 2035.

Growth Rate: 4.85%

-

Sector Contributions: Growth in the market is driven by: -

Manufacturing and Supply Chain Optimization: The rising demand for hydrogen peroxide in industries such as pulp and paper, textiles, and chemicals mandates the utilization of real-time data and integrated processes to improve production and distribution operations. -

Retail and E-Commerce Growth: As the need for hydrogen peroxide in cleaning, sanitization, and packaging grows, retailers and e-commerce businesses are implementing new solutions to improve supply chain efficiency, inventory management, and consumer engagement. -

Technological Advancements: AI and automation are improving hydrogen peroxide manufacturing procedures, allowing for predictive maintenance, streamlined supply chain management, and lower operating costs. -

Innovations: Modern, modular production procedures allow manufacturers to modify their hydrogen peroxide formulas for individual applications, decreasing waste and increasing cost-effectiveness. -

Investment Initiatives: Companies are investing in cutting-edge manufacturing technology, digital tools, and sustainable practices to create cost savings, decrease environmental impact, and maintain market competitiveness. -

Regional Insights: Asia Pacific and North America continue to be important hubs for hydrogen peroxide production, owing to strong industrial expansion, chemical industry innovation, and rising demand for sustainable products.

Key Trends and Sustainability Outlook:

-

Digital Transformation: Digitization is occurring throughout the hydrogen peroxide value chain, from procurement to manufacturing, allowing organizations to track real-time data, optimize operations, and effectively manage inventory. -

Advanced Features: By integrating smart technologies like as AI, IoT, and data analytics, hydrogen peroxide producers may improve process efficiency, increase transparency, and satisfy tough sustainability targets. -

Focus on Sustainability: Hydrogen peroxide is increasingly being employed as an environmentally friendly alternative in a variety of industries, with an emphasis on green chemistry and waste reduction. -

Customization Trends: The increased need for customized hydrogen peroxide solutions, notably in healthcare, textile, and environmental applications, is propelling the development of industry-specific products.

-

Data-Driven Insights: Data analytics and real-time monitoring enable businesses to better estimate demand, manage production, and track environmental implications.

Growth Drivers:

-

Digital Transformation: The rise of digital technology is revolutionizing the hydrogen peroxide market, enabling organizations simplify operations, cut manufacturing costs, and improve supply chain visibility. -

Demand for Process Automation: The increased use of automation in chemical production processes is eliminating operating bottlenecks, increasing efficiency, and reducing human error in hydrogen peroxide manufacturing. -

Scalability Requirements: As global demand for hydrogen peroxide develops, businesses want scalable production methods that can handle fluctuating quantities and adapt to changing market dynamics. -

Regulatory Compliance: As the chemical industry faces increased regulatory scrutiny, hydrogen peroxide producers are turning to digital tools and software to assure environmental, health, and safety compliance. -

Globalization: The increasing use of hydrogen peroxide in sanitization and wastewater treatment is generating demand for goods that support global supply chain operations, such as multi-currency and international compliance features.

Overview of Market Intelligence Services for the Hydrogen Peroxide Market:

Recent research has identified important issues in the hydrogen peroxide market, including variable raw material prices and the need for sustainable production processes. Market intelligence studies provide practical insights into procurement prospects, allowing businesses to uncover cost-cutting initiatives, optimize supplier management, and enhance overall procurement strategies. These insights also help to ensure compliance with industry standards and maintain high-quality operational procedures while successfully controlling costs.

Procurement Intelligence for Hydrogen Peroxide: Category Management and Strategic Sourcing

To remain competitive in the hydrogen peroxide industry, businesses are improving their procurement procedures through spend monitoring and supplier performance tracking. Effective category management and strategic sourcing are essential for lowering procurement costs while maintaining a consistent supply of high-quality raw materials and products. By leveraging actionable market intelligence, Businesses may improve their procurement strategy, negotiate better terms with suppliers, and ensure a consistent and cost-effective hydrogen peroxide supply to meet rising demand.

Pricing Outlook for Hydrogen Peroxide: Spend Analysis

The pricing prognosis for hydrogen peroxide is projected to be moderately dynamic, with potential changes caused by a variety of variables. Production technology developments, rising demand across industries, regional pricing variances, and changes in environmental regulations are all major drivers. Furthermore, the growing emphasis on sustainability, combined with rising demand for environmentally friendly alternatives, is putting upward pressure on hydrogen peroxide prices.

Graph shows general upward trend pricing for Hydrogen Peroxide and growing demand. However, there may be fluctuations influenced by economic conditions, technological advancements, and competitive dynamic.

Efforts to optimize procurement processes, improve supplier management, and investigate sustainable manufacturing choices are critical for minimizing costs in the hydrogen peroxide market. Using digital tools for market monitoring, analytics to forecast price patterns, and effective contract management can further enhance cost efficiency.

Partnering with reputable hydrogen peroxide providers, negotiating long-term contracts, and contemplating bulk purchase or subscription-based models are all useful techniques for managing procurement costs. Despite these hurdles, prioritizing scalability, ensuring supply chain resilience, and implementing eco-friendly production processes will be crucial to preserving cost-effectiveness and operational efficiency.

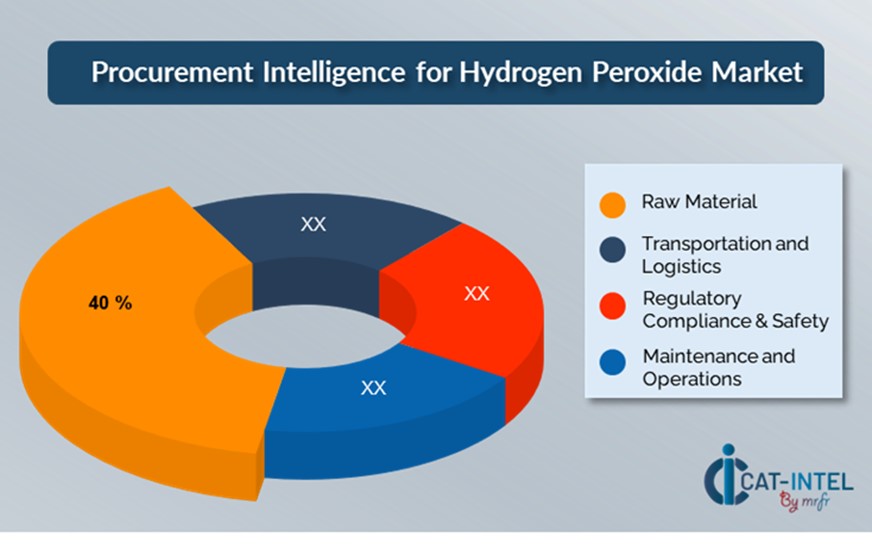

Cost Breakdown for Hydrogen Peroxide: Total Cost of Ownership (TCO) and Cost-Saving Opportunities

- Raw Material: (40%)

-

Description: The raw material and production costs refer to the expenditures incurred during the synthesis of hydrogen peroxide, which include the cost of raw chemicals, energy, labour, and manufacture. -

Trend Point: The growing need for environmentally friendly production methods is prompting enterprises to use green chemistry to produce hydrogen peroxide.

- Transportation and Logistics: (XX%)

- Regulatory Compliance & Safety: (XX%)

- Maintenance and Operation: (XX%)

Cost-Saving Opportunities: Negotiation Levers and Purchasing Negotiation Strategies

In the hydrogen peroxide industry, streamlining procurement processes and employing strategic negotiation strategies can result in significant cost savings and increased operational efficiency. Long-term collaborations with hydrogen peroxide providers, particularly those that provide sustainable or eco-friendly solutions, can result in more competitive pricing structures, volume-based discounts, and bundled service packages. Negotiating bulk purchasing agreements or subscription-based contracts can result in lower rates and help to reduce price variations over time.

Partnering with hydrogen peroxide providers who value innovation, sustainability, and scalability can lead to additional benefits such as improved production methods, eco-friendly formulations, and long-term cost savings. Using digital technologies for procurement, such as contract management systems and use analytics, increases transparency, reduces waste, and assures effective supply chain management. Diversifying vendor options and implementing a multi-supplier strategy can help reduce reliance on a single provider, mitigate risks such as supply chain disruptions, and increase negotiating leverage to secure favourable terms, resulting in a consistent supply of superior hydrogen peroxide at competitive pricing.

Supply and Demand Overview for Hydrogen Peroxide: Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The hydrogen peroxide market is expanding steadily, propelled by rising demand in major industries including pulp and paper, textiles, food and beverage, medical care, and environmental applications. Technological improvements, regulatory constraints, and global economic situations all have an impact on supply and demand dynamics, as do shifts in consumer preferences for sustainable and environmentally friendly solutions.

Demand Factors:

-

Sustainable Beneficial Initiatives: The growing emphasis on green chemistry and environmental sustainability is boosting demand for hydrogen peroxide as a safer option in industrial applications such as wastewater treatment and disinfection. -

Technological Advancements: Innovations in production technology, such as more efficient manufacturing processes and improved formulations, are increasing demand for high-quality hydrogen peroxide across multiple industries. -

Industry-Specific Requirements: Healthcare, food processing, and textile industries demand hydrogen peroxide solutions that adhere to strict regulatory standards, safety protocols, and operational processes. -

Versatility and Efficiency: The rising demand for versatile chemicals in industrial applications including sterilizing, cleaning is fuelling the need for hydrogen peroxide as a cost-effective solution across various sectors.

Supply Factors:

-

Technological Advancements: AI, automation, and more efficient production methods are boosting hydrogen peroxide manufacturing, lowering costs and increasing product quality. -

Vendor Ecosystem: The expanding number of hydrogen peroxide providers, including both large-scale and specialist producers, offers businesses with a variety of options and increases market competition. -

Global Economic Factors: Exchange rates, shipping costs, and regional technological adoption rates all have an impact on the supply and pricing of hydrogen peroxide, especially when global trade dynamics vary. -

Scalability and Flexibility: Modern manufacturing technologies make hydrogen peroxide more scalable and versatile, allowing providers to fulfil the changing needs of various industries.

Regional Demand-Supply Outlook: Hydrogen Peroxide

The Image shows growing demand for Hydrogen Peroxide in both Asia Pacific and North America, with potential price increases and increased Competition.

Asia Pacific: Dominance in the Hydrogen Peroxide Market

Asia Pacific, particularly China, is a dominant force in the global Hydrogen Peroxide market due to several key factors:

-

Strong Trade Networks: With robust trade linkages and rising demand for hydrogen peroxide in other countries, the Asia-Pacific region remains the leader in production and distribution. -

Rising Environmental Awareness: Industries are increasingly employing hydrogen peroxide for water treatment, waste management, and cleaning, which aligns with environmental sustainability aims. -

End-User Industry Expansion: Key end-user industries in the Asia-Pacific region are rapidly expanding, including healthcare, food processing, and water treatment. -

Industrial Growth and Demand: Hydrogen peroxide is used extensively in key industries such as textiles, pulp and paper, chemicals, and pharmaceuticals for bleaching, sterilizing, and chemical synthesis. -

Cost-Effective Production: Countries such as China have well-established production infrastructures that take advantage of cheaper labour costs, economies of scale, and raw material availability.

Asia Pacific Remains a key hub Hydrogen Peroxide Price Drivers Innovation and Growth

Supplier Landscape: Supplier Negotiations and Strategies

The hydrogen peroxide market has a broad and competitive supplier landscape, with global industry giants and regional suppliers all affecting critical criteria such as pricing strategies, product quality, and manufacturing capacities. Large-scale manufacturers dominate the market, providing a diverse range of hydrogen peroxide grades, whilst smaller, specialist suppliers focus on specific uses, such as environmentally friendly compositions or industry-specific solutions.

Supplier ecosystem includes important worldwide manufacturing hubs as well as creative local businesses that cater to specific industrial demands. Prominent global suppliers dominate the market with mass manufacturing capabilities, but smaller, regional competitors frequently customize their solutions to satisfy the regulatory and operational requirements of certain industries such as healthcare, textiles, and environmental services. As businesses place a greater emphasis on sustainability, efficiency, and modern production methods, hydrogen peroxide suppliers are investing in innovative manufacturing processes, greener formulations, and digital technology to optimize production. Many vendors also provide variable pricing models and long-term contracts to meet changing business needs and give cost-effective solutions.

Key Suppliers in the Hydrogen Peroxide Market Include:

- China National Petroleum Corporation (CNPC)

- Solvay Group

- Evonik Industries

- Akzo Nobel

- BASF

- Dow Chemical Company

- Linde Group

- Mitsubishi Gas Chemical Company

- Saudi Basic Industries Corporation (SABIC)

- Arkema

Key Developments Procurement Category Significant Development:

Significant Development |

Description |

Market Growth |

The hydrogen peroxide market is expanding rapidly, driven by rising demand in industries such as pulp & paper, textiles, healthcare, and environmental applications. |

Cloud Adoption |

Cloud technologies enable better inventory management, demand forecasting, and real-time data exchange across manufacturers, suppliers, and distributors, hence increasing total supply chain visibility and efficiency. |

Product Innovation |

Suppliers in the hydrogen peroxide market are enhancing their product offerings by providing more sustainable and efficient solutions. For example, advances in hydrogen peroxide compositions with lower environmental effect are becoming more visible. |

Technological Advancements |

Machine learning algorithms and IoT-enabled devices assist optimize manufacturing processes, increase safety measures, and predict maintenance requirements, all of which contribute to the industry's overall trend toward more sustainable production practices. |

Global Trade Dynamics |

Multinational corporations with complicated supply chains are increasingly dependent on hydrogen peroxide providers who can manage changing trade regulations while maintaining consistent product quality and meeting regulatory requirements. |

Customization Trends |

Modular and flexible hydrogen peroxide manufacturing systems are being created, allowing businesses to tailor their solutions, such as modifying concentrations or developing specific applications, to their specific needs. |

|

Hydrogen Peroxide Attribute/Metric |

Details |

Market Sizin |

The global Hydrogen Peroxide market is projected to reach USD 5.43 billion by 2035, growing at a CAGR of approximately 4.85% from 2025 to 2035. |

Hydrogen Peroxide Technology Adoption Rate |

Approximately 60% of firms in important industries such as textiles, pulp & paper, and healthcare use hydrogen peroxide for an assortment of applications, with an increasing emphasis on environmentally benign and sustainable solutions. |

Top Hydrogen Peroxide Industry Strategies for 2025 |

Adopting greener manufacturing methods, improving product formulations for specific industrial demands, simplifying supply chain logistics, and investigating new uses such as water treatment and sanitation are all important measures. |

Hydrogen Peroxide Process Automation |

Around 45% of hydrogen peroxide production processes are becoming more automated, notably in areas such as inventory management, quality control, and waste reduction, which improves production efficiency. |

Hydrogen Peroxide Process Challenges |

Major issues include raw material pricing variations, environmental regulatory compliance, product uniformity, and managing global demand swings. |

Key Suppliers |

China National Petroleum Corporation (CNPC), Solvay Group and Evonik Industries are the leading hydrogen peroxide suppliers, offering a range of products.

|

Key Regions Covered |

Asia Pacific, North America and Europe are major markets for hydrogen peroxide, with significant use in the pulp & paper, textile, and environmental sectors. |

Market Drivers and Trends |

Growth is being driven by rising demand for environmentally friendly solutions, developments in hydrogen peroxide manufacturing technologies, automation integration for cost savings, and increased application in a variety of industries such as sanitation, healthcare, and water treatment. |