Summary Overview

Glycerin Market Overview:

The global Glycerin market is steadily expanding, propelled by rising demand in industries such as cosmetics, pharmaceuticals, food and drinks, and biofuels. This market includes synthetic, natural, and bio-based glycerin solutions. Our research provides a detailed examination of procurement trends, with a focus on cost-cutting techniques and the use of digital tools to improve procurement and operations processes.

Key future issues in glycerin procurement include cost management, consistent supply chains, regulatory compliance, and product quality. The increasing emphasis on sustainability and environmental concerns is also influencing market dynamics. Digital tools and strategic sourcing are critical for improving glycerin procurement, maintaining a competitive advantage, and satisfying changing consumer needs.

Market Size: The global Glycerin market is projected to reach USD 6.03 billion by 2035, growing at a CAGR of approximately 5.64% from 2025 to 2035.

Growth Rate: 5.64%

Sector Contributions: Growth in the market is driven by:

Manufacturing and Supply Chain Optimization: Companies are increasingly using digital solutions to optimize production schedules, track inventory levels, and assure smooth transportation to sustain product availability across many markets.

Retail and E-commerce Growth: Efficient inventory management and demand forecasting enabled by AI and machine learning are becoming increasingly important for matching changing consumer demands.

Technological Transformation: Digital technologies like as AI, machine learning, and automation are improving glycerin production processes. These technologies enable predictive analytics, greater quality control, and computerized production lines, resulting in increased operational efficiency and cost savings.

Innovations in Glycerin Production: The market is experiencing innovation, including the introduction of bio-based and sustainable glycerin products. This decreases the environmental impact and meets the growing customer demand for eco-friendly ingredients.

Investment Initiatives: Investments in sustainable glycerin manufacturing technologies, such as those derived from plants, are being prioritized as part of larger environmental goals.

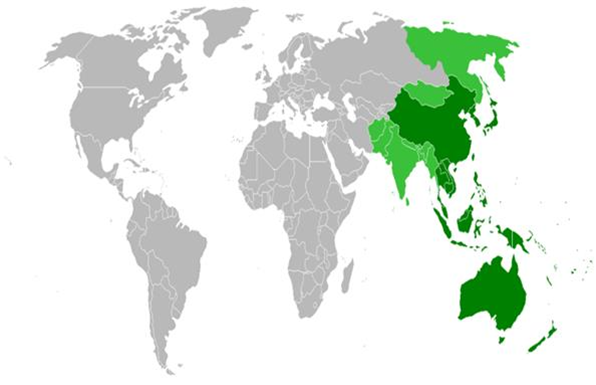

Regional Insights: The Asia-Pacific and North American regions dominate the glycerin market due to their strong industrial bases and rising demand for glycerin in industries such as personal care and biofuels.

Key Trends and Sustainability Outlook:

Sustainability Focus: The glycerin business is moving toward more sustainable and bio-based glycerin, with companies striving to lessen dependency on petroleum-based supplies.

Advanced Features: The integration of AI, IoT, and blockchain improves supply chain transparency, product traceability, and decision-making along the glycerin value chain.

Focus on Sustainability: Manufacturers are focused on sustainable raw material procurement, such as employing renewable feedstocks (e.g., waste oils or algae) rather than typical palm or soy oils, which can have negative environmental consequences such as deforestation.

Customization Trends: The demand for industry-specific glycerin products is increasing, with formulations adjusted to satisfy the distinct needs of sectors like food, cosmetics and pharmaceuticals.

Data-Driven Insights: As the global glycerin supply chain becomes more complicated, companies use advanced analytics to estimate demand, optimize inventory, and measure production efficiency.

Growth Drivers:

Digital Transformation: As organizations use more digital technologies, they enhance the efficiency of glycerin production and distribution, hence increasing operational productivity.

Demand for Process Automation: The growing dependence on automation in production and logistics is decreasing bottlenecks and increasing operational efficiency in the glycerin industry.

Scalability Requirements: Glycerin producers are investing in flexible production systems that can scale with market demand, guaranteeing that they can satisfy the needs of growing markets and sectors.

Regulatory Compliance: Adherence to environmental and safety requirements, particularly in the food and pharmaceutical industries, drives innovation and raises product standards in glycerin production.

Globalization: The expansion of worldwide trade and supply chains is driving demand for glycerin solutions that can fulfill a variety of international standards and requirements across multiple areas.

Overview of Market Intelligence Services for the Glycerin Market:

Recent evaluations of the glycerin business have highlighted important concerns such as increased production costs and the need for sustainable sourcing alternatives. Market intelligence reports offer useful insights into procurement prospects, assisting businesses in identifying cost-cutting initiatives, optimizing supplier relationships, and improving the efficiency of production processes. These insights also help to ensure environmental compliance and high-quality operating operations, all while effectively controlling expenses.

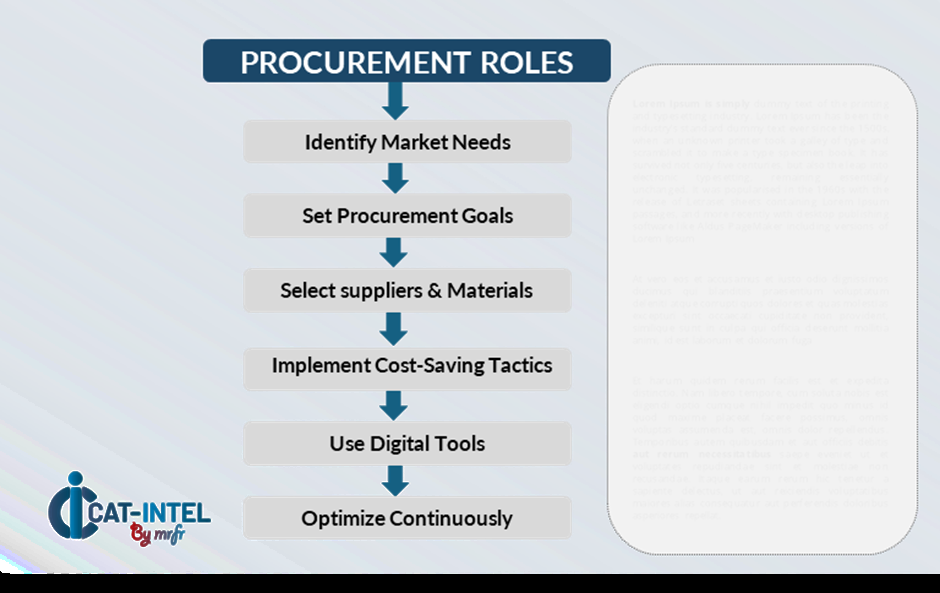

Procurement Intelligence for Glycerin: Category Management and Strategic Sourcing

To remain competitive in the glycerin market, firms are improving procurement processes through expenditure analysis and vendor performance tracking. Effective category management and strategic sourcing are critical for lowering procurement costs and guaranteeing a consistent supply of high-quality glycerin from reputable suppliers. Companies that use actionable market knowledge can fine-tune their procurement strategy, negotiate better deals with suppliers, and improve the sustainability of their glycerin sourcing methods. This strategy is critical for sustaining long-term competitiveness and satisfying changing market expectations for environmentally sustainable and cost-effective glycerin solutions.

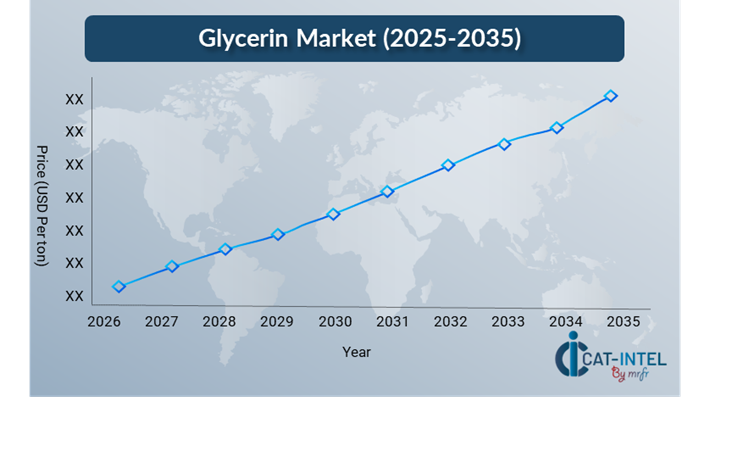

Pricing Outlook for Glycerin: Spend Analysis

The pricing prognosis for glycerin is projected to remain moderately dynamic, with potential changes caused by a variety of variables. Production technology developments, rising demand for bio-based and sustainable glycerin, regulatory restrictions, and regional pricing variances are all important factors to consider. Furthermore, the growing emphasis on sustainable sourcing practices, along with an increased attention on supply chain transparency and compliance with environmental standards are leading to rising pressure on glycerin prices.

Graph shows general upward trend pricing for Glycerin and growing demand. However, there may be fluctuations influenced by economic conditions, technological advancements, and competitive dynamic.

Efforts to optimize procurement procedures, strengthen supplier relationships, and implement flexible sourcing techniques are critical for controlling glycerin prices. Leveraging digital technologies for market monitoring, pricing forecasting, and effective contract management can help you reduce costs even further.

Partnering with reputable glycerin suppliers, negotiating long-term contracts, and investigating bulk or subscription-based purchasing models are all important techniques for effectively managing glycerin expenses. Regardless of these obstacles, concentrating on sustainability, keeping a stable supply chain, and implementing novel production methods will be crucial to preserving cost-effectiveness and operational efficiency in the glycerin market.

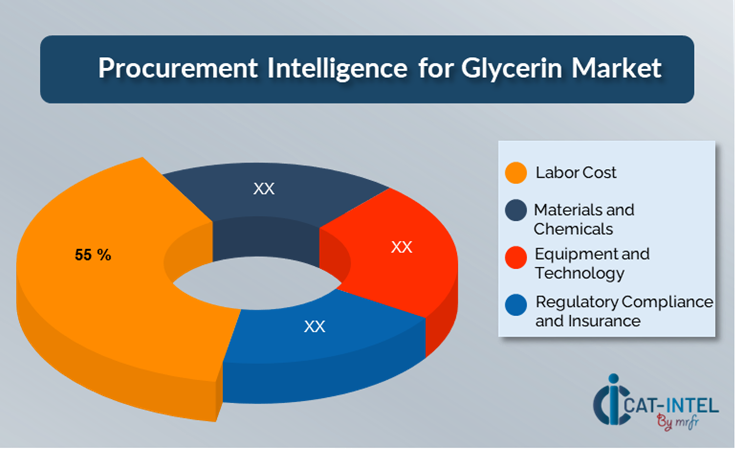

Cost Breakdown for Glycerin: Total Cost of Ownership (TCO) and Cost-Saving Opportunities

Raw Material: (55%)

Description: Vegetable oils (such as palm oil and soybean oil) and animal fats are the principal raw materials used in glycerin manufacturing. These expenses have a considerable impact on the entire price of glycerin, as raw material prices change according to market conditions.

Trend: Raw material source is becoming more sustainable, with a focus on renewable bio-based glycerin manufacturing.

Production and Manufacturing: (XX%)

Logistics and Distribution: (XX%)

Regulatory Compliance and Sustainability: (XX%)

Cost-Saving Opportunities: Negotiation Levers and Purchasing Negotiation Strategies

In the glycerin market, streamlining procurement processes and using effective bargaining strategies can result in significant cost savings and increased operational efficiency. Long-term relationships with glycerin suppliers, particularly those focusing on sustainable and bio-based manufacturing, can result in improved price structures and more favourable terms, such as bulk purchase discounts and bundled supply packages. Subscription-based models and multi-year contracts provide chances to lock in reduced rates while mitigating the impact of price variations over time.

Collaborating with glycerin suppliers who value innovation and sustainability can provide additional benefits like as access to eco-friendly production techniques and traceability solutions, which assist lower long-term operational expenses. Implementing digital procurement solutions, such as contract management systems and demand forecasting platforms, improves transparency, reduces overstocking, and assures optimal use of glycerin supplies. Diversifying supplier relationships and using multi-vendor techniques can decrease reliance on a single provider, reduce risks, and boost negotiating leverage, resulting in a more resilient and cost-effective glycerin supply chain.

Supply and Demand Overview for Glycerin: Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The glycerin market is steadily expanding, driven by rising demand from a variety of industries including personal care, pharmaceuticals, food and drinks, and industrial applications. Technological developments in glycerin production, regulatory regulations, and changing global economic conditions all have an impact on supply and demand dynamics.

Demand Factors:

Sustainability Trends: Rising environmental awareness and demand for eco-friendly products are propelling the use of bio-based glycerin, particularly from renewable sources such as plant oils.

Industrial and Consumer Demand: Growing use of glycerin in personal care items, medicines, and food processing is driving market growth.

Regulatory Compliance: Glycerin solutions that fulfill certain industry standards, such as food-grade and pharmaceutical-grade certifications, are becoming increasingly popular across a wide range of industries.

Integration with Other Ingredients: Demand for glycerin in formulations that integrate seamlessly with other active chemicals is increasing, particularly in cosmetics and pharmaceuticals.

Supply Factors:

Technological Advancements: The utilization of bio-based feedstocks, new distillation technologies, and sustainable manufacturing techniques are increasing glycerin supply while decreasing costs.

Vendor Ecosystem: A rising number of vendors, ranging from major multinational producers to smaller, specialized enterprises, offer a wide range of glycerin solutions to meet the needs of various markets.

Global Economic Factors: Glycerin pricing and availability vary by area, depending on trade regulations, economic conditions, and raw material cost swings.

Scalability and Flexibility: Modern glycerin manufacturing processes are becoming more modular and adaptable, allowing suppliers to scale production to meet the demands of various industries, ranging from small-scale to big pharmaceutical applications.

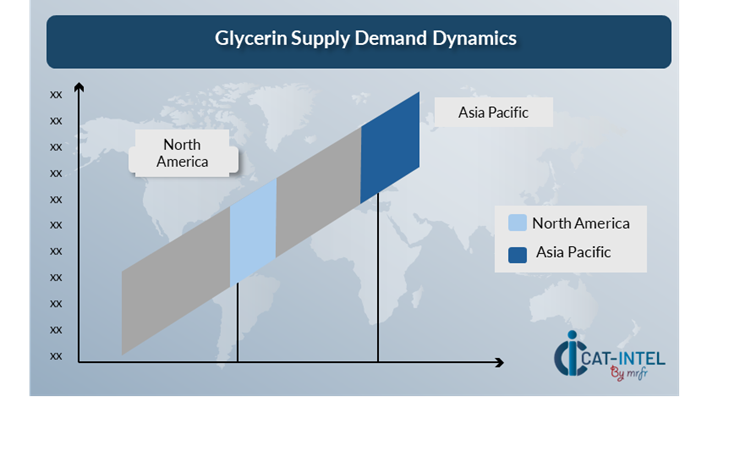

Regional Demand-Supply Outlook: Glycerin

The Image shows growing demand for Glycerin in both Asia Pacific and North America, with potential price increases and increased Competitionsia Pacific: Dominance in the Glycerin Market

Asia Pacific, particularly China, is a dominant force in the Glycerin market due to several key factors:

Strong Manufacturing Base: Asia-Pacific, especially countries like as The region is home to various glycerin production facilities that serve both domestic and foreign markets, making it a global manufacturing hub.

Raw Material Availability: The region's capacity to obtain these raw materials at competitive costs enables it to maintain a strong position in the glycerin industry.

Cost-Effective Production: Many Asian-Pacific countries have cheaper labor and production costs, giving glycerin producers a competitive advantage.

Expanding Demand from End-Use Industries: The region's expanding middle-class population and increased disposable income drive up demand for these items, boosting glycerin consumption.

Export Strength: Countries such as China, Malaysia, and Indonesia are major glycerin exporters, thanks to robust trade relations, infrastructure, and logistics. A sia Pacific Remains a key hub Glycerin Price Drivers Innovation and Growth.

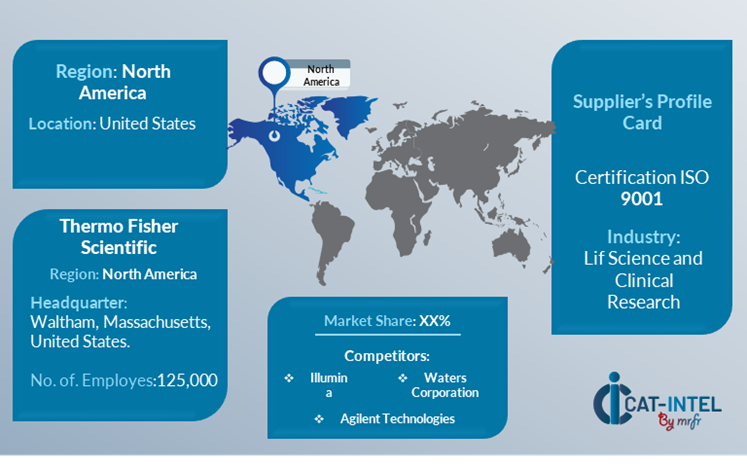

Supplier Landscape: Supplier Negotiations and Strategies

The supplier environment in the glycerin market is diversified and competitive, with a mix of global and regional producers influencing industry dynamics. These suppliers have an impact on key elements such as price structures, production capacity, and product quality. Large multinational firms dominate the market, offering a diverse range of glycerin products, while smaller, specialized providers specialize in specific uses such as bio-based glycerin or environmentally friendly manufacturing methods.

The glycerin supplier ecosystem spans significant geographical regions, including Asia Pacific, North America and Europe, with local producers meeting region-specific demands. As businesses prioritize sustainability and environmentally friendly solutions, glycerin suppliers are expanding production capacity, implementing greener technologies, and investigating alternative sources, such as renewable feedstocks. Furthermore, suppliers are providing more flexible pricing structures and value-added services to address the changing needs of industries such as personal care, pharmaceuticals, food and drinks, and industrial applications.

Key Suppliers in the Glycerin Market include:

Wilmar International Limited

Cargill, Inc.

Kraton Polymer

Procter & Gamble Chemicals

The Dow Chemical Company

BASF SE

Stepan Company

Emery Oleochemicals

Kratom Polymers

Glory Oil

Key Developments Procurement Category Significant Development:

Significant Development |

Description |

Market Growth |

The glycerin market is expanding rapidly, driven by its increasing use in a variety of industries, including personal care, pharmaceuticals, food & drinks, and industrial applications. |

Cloud Adoption |

There is a growing trend toward bio-based glycerin solutions, driven by growing consumer and regulatory demand for ethical and ecologically acceptable products. Manufacturers are using glycerin derived from renewable resources such as plant oils to reduce their emissions and satisfy environmental targets. |

Product Innovation |

Glycerin blends and formulas designed for specific uses, such as anti-aging skincare, medical applications, and improved food preservation procedures, are further examples of innovation. |

Technological Advancements |

Technological advances in glycerin manufacturing, such as enhanced distillation and fermentation methods, are increasing the efficiency of glycerin extraction and refining. Furthermore, advances in glycerin-based formulations, such as the inclusion of glycerin into next-generation biodegradable plastics, are creating new markets and application opportunities.

|

Global Trade Dynamics |

Global trade restrictions, including as taxes, environmental standards, and compliance requirements, have an impact on the glycerin market, particularly for multinational firms with various supply chains. For example, trade regulations that promote bio-based and sustainable raw resources increase demand for glycerin derived from renewable sources.

|

Customization Trends |

There is increasing demand for glycerin products that are adapted to specific industry needs. Custom glycerin formulations are becoming increasingly common, especially in areas like cosmetics, medicines, and food and drinks, which require unique processing and regulatory criteria require highly specific solutions.

|

Glycerin Attribute/Metric |

Details |

Market Sizing |

The global Glycerin market is projected to reach USD 6.03 billion by 2035, growing at a CAGR of approximately 5.64% from 2025 to 2035.

|

Glycerin Technology Adoption Rate |

Around 60% of enterprises in the personal care, food, and pharmaceutical industries worldwide have incorporated glycerin-based solutions into their goods, with a noticeable move toward eco-friendly and bio-based glycerin derived from renewable feedstocks to fulfill customer demands.

|

Top Glycerin Industry Strategies for 2025 |

Key strategies for glycerin suppliers include increasing sustainability by offering bio-based glycerin products, implementing innovative glycerin production technologies, expanding into emerging markets, and focusing on advanced glycerin formulations tailored to specific industries such as personal care, pharmaceuticals, and food and beverages.

|

Glycerin Process Automation |

To improve operational efficiency and minimize production costs, almost 50% of glycerin production facilities have automated their manufacturing processes, including automated refining, distillation, and packing.

|

Glycerin Process Challenges |

Key problems in the glycerin market include variable raw material prices, sustainability constraints, uneven supply chains, and high manufacturing cost for bio-based glycerin. Furthermore, market competitors encounter problems in increasing production to fulfill expanding worldwide demand while adhering to environmental standards and industry laws.

|

Key Suppliers |

Leading glycerin suppliers include Wilmar International Limited, Cargill, Inc. and Kraton Polymer, they provide a diverse selection of grades, including industrial-grade, food-grade, and pharmaceutical-grade glycerin for a variety of uses.

|

Key Regions Covered |

Asia-Pacific, North America and Europe are important locations for glycerin adoption, with high demand in industries such as personal care, pharmaceuticals, food and drinks, and industrial uses .

|

Market Drivers and Trends |

The glycerin market is being pushed by rising demand for sustainable, bio-based, and multifunctional ingredients across a variety of sectors. Furthermore, customer preferences for environmentally friendly products, combined with regulatory demands to embrace sustainable practices, are driving the expansion of glycerin products derived from renewable feedstocks, particularly in the personal care and food sectors.

|