Summary Overview

LDPE (Low Density Polyethylene) Market Overview:

The global Low-Density Polyethylene (LDPE) market is steadily expanding, fuelled by rising demand in industries such as packaging, automotive, healthcare, and construction. This market covers a wide range of LDPE applications, including film, injection molding, and blow molding. Our paper provides a comprehensive examination of procurement trends, with an emphasis on cost-cutting initiatives and the use of innovative technology to improve procurement and operational procedures.

Key future problems in LDPE procurement include managing raw material price volatility, assuring constant product quality, adhering to sustainability standards, and improving supply chain efficiency. Digital tools and strategic sourcing are critical for driving successful procurement, optimizing production workflows, and maintaining long-term competitiveness. As global demand grows, firms use market intelligence to improve operational efficiency and reduce risk.

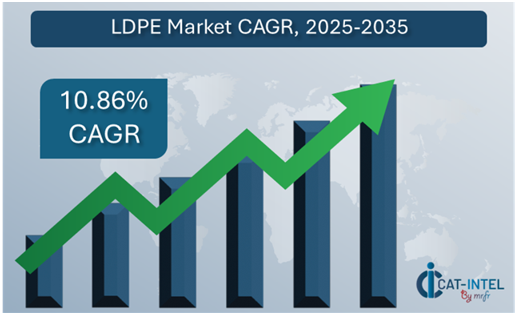

Market Size: The global LDPE (Low Density Polyethylene) market is projected to reach USD 181.62 billion by 2035, growing at a CAGR of approximately 10.86% from 2025 to 2035.

Growth Rate: 10.86%

-

Sector Contributions: Growth in the market is driven by: -

Manufacturing and Supply Chain Optimization: There is a growing need for real-time data and integrated procedures to optimize LDPE manufacturing and supply chains. -

Retail and E-commerce: LDPE remains a vital material for flexible packaging solutions that enhance product safety and consumer happiness.

-

-

Technological Advancements: Automation and material science are improving LDPE manufacturing capabilities, increasing production efficiency, and lowering waste. -

Material Innovations: As businesses face growing pressure to lessen their environmental impact, LDPE manufacturers are adding recycled materials into their products. -

Investment Initiatives: Advancements in processing technologies such as extrusion and molding are improving the manufacturing of LDPE for a variety of applications. -

Regional Insights: Asia-Pacific and North America remain major markets for LDPE development, owing to strong industrial manufacturing and rising demand in the packaging and construction industries.

Key Trends and Sustainability Outlook:

-

Supply Chain Optimization: Digital tools improve supply chain transparency, material traceability, and help manage raw material price volatility. -

Focus on Sustainability: As the need for ecologically friendly materials grows, LDPE manufacturers are working to improve recyclability and find biodegradable alternatives.

-

Regulatory Compliance: Increased regulation of plastic production and disposal is encouraging LDPE manufacturers to innovate in product design and recycling procedures. -

Customization Trends: Companies are designing LDPE solutions to satisfy industry-specific needs, including as food-grade packaging, medical applications, and durable construction materials.

Growth Drivers:

-

Digital Transformation: The LDPE market is experiencing an increase in demand for smarter production facilities, better forecasting, and real-time monitoring systems. -

Sustainability Focus: As circular economies and sustainable sources become more important, LDPE is being positioned for recycling and eco-friendly solutions. -

Demand for Process Automation: Companies are increasingly using automation in LDPE production to cut labor costs, enhance throughput, and ensure product uniformity. -

Scalability Needs: Manufacturers are looking for scalable solutions to fulfill rising demand, notably in the packaging and construction sectors, while managing variable raw material prices. -

Globalization: Manufacturers seek solutions that facilitate worldwide trade and multi-market operations, as well as compliance with regional norms and regulations.

Overview of Market Intelligence Services for the LDPE (Low Density Polyethylene) Market:

Recent investigations have identified important issues, such as variable raw material prices and the necessity for consistent material quality. Market intelligence studies provide useful insights into procurement opportunities, allowing businesses to identify cost-saving strategies, optimize supplier management, and assure a more efficient supply chain. These insights also help businesses comply with industry standards, maintain product quality, and manage costs effectively in the face of increasing demand for LDPE across various sectors.

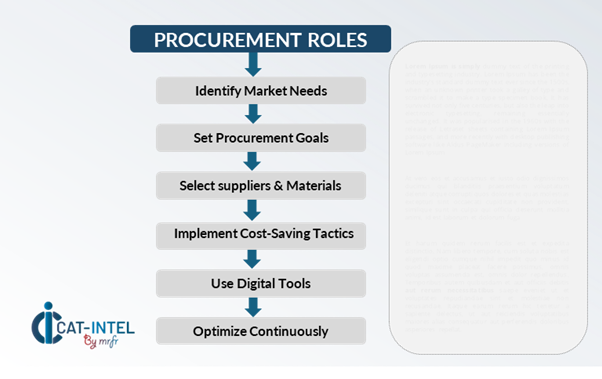

Procurement Intelligence for LDPE (Low Density Polyethylene): Category Management and Strategic Sourcing

To remain competitive in the LDPE market, businesses are optimizing their procurement processes with precise expenditure monitoring and vendor performance tracking. Effective category management and strategic sourcing are critical for lowering procurement costs, obtaining high-quality raw materials, and assuring a steady supply. Companies are examining procurement spend to seek cost reduction opportunities, such as bulk purchase, long-term contracts, or renegotiating supplier terms. Monitoring supplier performance is critical in the LDPE industry to ensure that suppliers adhere to quality requirements and delivery deadlines.

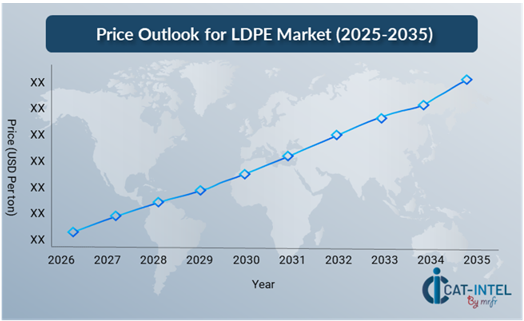

Pricing Outlook for LDPE (Low Density Polyethylene): Spend Analysis

The pricing prognosis for LDPE is projected to be moderately dynamic, with changes caused by a range of causes. Changes in raw material prices, developments in production technology, and demand for sustainable and high-performance materials are all key factors, and regional pricing differences. Furthermore, rising demand for eco-friendly packaging solutions, combined with increased pressure on producers to comply with environmental rules, is driving up LDPE pricing.

Graph shows general upward trend pricing for LDPE (Low Density Polyethylene) and growing demand. However, there may be fluctuations influenced by economic conditions, technological advancements, and competitive dynamic.

Efforts to streamline procurement procedures, improve supplier management, and obtain sustainable materials are critical to lowering costs in the LDPE sector. Using digital technologies, pricing forecasting, and supplier performance data can help businesses keep ahead of price variations and make educated purchasing decisions.

Regardless of price variations, firms must prioritize strategic sourcing, sustainability, and technological innovation in order to efficiently manage LDPE procurement costs while maintaining high-quality standards and operational excellence.

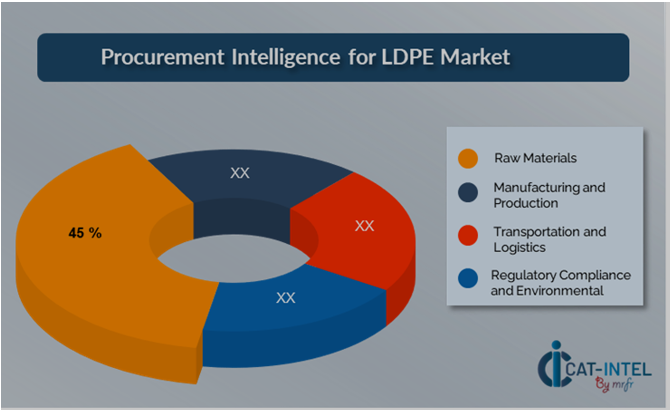

Cost Breakdown for LDPE (Low Density Polyethylene): Total Cost of Ownership (TCO) and Cost-Saving Opportunities

- Raw Materials: (45%)

-

Description: The biggest cost component in LDPE manufacture is the cost of raw materials, specifically ethylene generated from petroleum or natural gas. -

Trend: Price instability in global oil markets, as well as continuous movements toward sustainable feedstocks (e.g., bio-based ethylene), are influencing material prices.

-

- Manufacturing and Production: (XX%)

- Transportation and Logistics: (XX%)

- Regulatory Compliance and Environmental: (XX%)

Cost-Saving Opportunities: Negotiation Levers and Purchasing Negotiation Strategies

In the LDPE business, streamlining procurement processes and using strategic bargaining strategies can lead to significant cost reductions and increased operational efficiency. Establishing long-term partnerships with suppliers, particularly those who provide sustainable and high-quality LDPE solutions, can help businesses gain better pricing structures and more advantageous terms, such as volume-based discounts and bundled service packages.

Collaborating with LDPE suppliers who prioritize innovation in sustainable production methods and scalability provides long-term benefits. Access to more ecologically friendly production techniques and materials, such as recycled LDPE, can assist meet regulatory standards while also lowering total production costs. Suppliers who use sophisticated technologies into their operations can increase efficiency and improve cost control. Businesses can increase their bargaining power by working with many suppliers, ensuring more competitive pricing and flexibility.

Supply and Demand Overview for LDPE (Low Density Polyethylene): Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The LDPE market is steadily expanding, driven by rising demand for sustainable and flexible packaging solutions in industries such as food and beverage, healthcare, and consumer goods. The LDPE market's supply and demand dynamics are influenced by raw material costs, technological improvements in manufacturing processes, regulatory restrictions, and global economic situations.

Demand Factors:

-

Sustainability Initiatives: Manufacturers are increasingly using LDPE in eco-friendly packaging, contributing to increased demand in a variety of industries, including retail and consumer goods. -

Packaging Needs: There is a growing demand for lightweight, robust, and flexible packaging solutions, all of which LDPE excels at in industries such as food packaging, pharmaceuticals, and electronics. -

Regulatory Pressures: The increased adoption of plastic waste legislation and recycling standards is forcing businesses to seek more recyclable, environmentally friendly LDPE solutions. -

Customization and Product Innovation: Tailored LDPE solutions that fulfill industry-specific regulatory criteria and functional needs are becoming increasingly popular.

Supply Factors:

-

Technological Advancements: Advances in LDPE production, such as extrusion, molding, and recycling technologies, are increasing the efficiency and sustainability of LDPE production. -

Vendor Ecosystem: An increasing number of LDPE producers and suppliers have expanded the range of possibilities available to buyers, providing more specialized solutions to specific client needs. -

Global Economic Factors: Exchange rates, labor costs, and regional demand patterns all have an impact on LDPE pricing and supply. -

Sustainability and Recycling Efforts: As the demand for recycled LDPE grows, producers are concentrating on improving recycling methods and implementing technologies that allow LDPE products to be reused.

Regional Demand-Supply Outlook: LDPE (Low Density Polyethylene)

The Image shows growing demand for LDPE (Low Density Polyethylene) in both Asia Pacific and North America, with potential price increases and increased Competition.

Asia Pacific: Dominance in the LDPE (Low Density Polyethylene) Market

Asia Pacific, particularly Southeast Asia, is a dominant force in the global LDPE (Low Density Polyethylene) market due to several key factors:

-

Large Production Capacity: The region is a major producer of LDPE and other petrochemical goods, which contributes to its global dominance. -

Rapid Industrialization: Urbanization in Asia-Pacific have resulted in increased demand for materials such as LDPE, which is widely used in the packaging and healthcare industries. -

Growing Consumer Market: The region's robust economic growth drives up demand for consumer goods, packaging, and long-lasting plastics, all of which rely on LDPE. -

Access to Raw Materials: The Asia-Pacific area and the Middle East are home to many of the world's largest oil and gas reserves, which are used to produce polyethylene. -

Government Support and Policies: Numerous nations in Asia-Pacific have adopted favorable government policies to promote manufacturing, export activities, and infrastructure development.

North America Remains a key hub LDPE (Low Density Polyethylene) Price Drivers Innovation and Growth.

Supplier Landscape: Supplier Negotiations and Strategies

LDPE market has a highly competitive supplier landscape, with global industry giants and regional producers driving important market dynamics. These suppliers have a considerable impact on key elements such as pricing structures, material quality, manufacturing capabilities, and sustainability practices. Large-scale manufacturers dominate the market with high-volume LDPE solutions, while smaller, specialized suppliers focus on niche applications such as recycled LDPE or custom formulations for certain industries.

Along with global leaders, smaller regional and niche businesses are making their mark by focusing on specialized LDPE applications or providing distinctive features like as increased recyclability, eco-friendly production techniques, or low-impact manufacturing. As the need for ecologically friendly materials develops, LDPE suppliers are stressing sustainability in their products. This includes increasing manufacture of recycled LDPE as well as investment in more energy-efficient and environmentally friendly production techniques. Companies who can provide LDPE solutions that are consistent with circular economy concepts enjoy a competitive advantage in the marketplace.

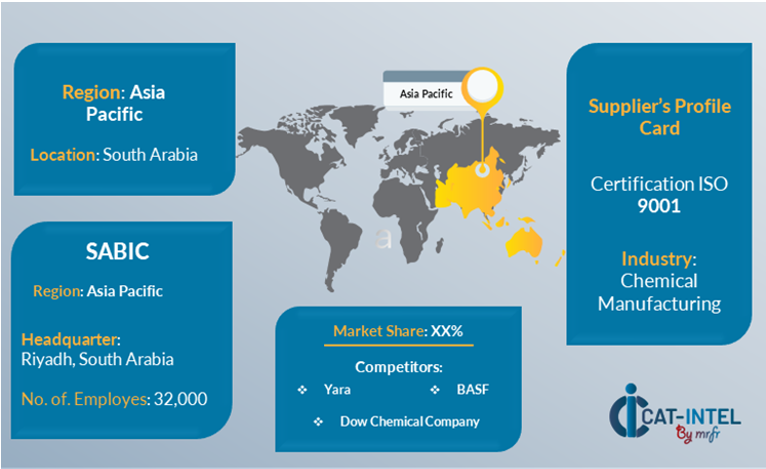

Key Suppliers in the LDPE (Low Density Polyethylene) Market Include:

- SABIC

- ExxonMobil Chemical

- Lyondell-Basell Industries

- Dow Chemical Company

- Chevron Phillips Chemical

- INEOS Group

- Reliance Industries

- Braskem

- LG Chem

- Formosa Plastics Corporation

Key Developments Procurement Category Significant Development:

Significant Development |

Description |

Market Growth |

The LDPE market is growing steadily, driven by rising demand for flexible, long-lasting, and environmentally friendly packaging solutions in industries such as food, healthcare, and e-commerce. |

Cloud Adoption |

Global environmental concerns and regulatory challenges are driving an increase in the need for sustainable LDPE solutions. The need for LDPE products that are recyclable, biodegradable, and have a low carbon footprint is increasing. |

Product Innovation |

LDPE suppliers are developing new formulations such as recycled LDPE (rLDPE), biodegradable variations, and multi-layered films to improve durability and functionality, allowing for the manufacture of lighter, more cost-effective, and sustainable LDPE products. |

Technological Advancements |

The LDPE manufacturing process is being transformed by innovations such as automated production systems, smart manufacturing technologies, and the integration of IoT devices for supply chain optimization. |

Global Trade Dynamics |

The increased emphasis on recycling and circular economies is resulting in stronger laws on plastic waste, influencing both supply and demand for LDPE materials. |

Customization Trends |

There is an increasing need for LDPE products that are suited to specific industrial requirements, such as food-safe packaging, medical-grade polymers, and specialty films for high-performance applications. |

|

LDPE (Low Density Polyethylene) Attribute/Metric |

Details |

Market Sizing |

The global LDPE (Low Density Polyethylene) market is projected to reach USD 181.62 billion by 2035, growing at a CAGR of approximately 10.86% from 2025 to 2035. |

LDPE (Low Density Polyethylene) Technology Adoption Rate |

Around 60% of manufacturers worldwide are implementing sophisticated technology for LDPE production, such as automated extrusion systems and smart manufacturing processes, to improve efficiency and sustainability.

|

Top LDPE (Low Density Polyethylene) Industry Strategies for 2025 |

Key goals include increasing the usage of recycled LDPE, implementing environmentally friendly manufacturing methods, improving product durability with multi-layer films, and reacting to the growing demand for biodegradable plastics.

|

LDPE (Low Density Polyethylene) Process Automation |

To improve production efficiency and save costs, over 50% of LDPE manufacturing facilities automate important processes including as extrusion, molding, and quality control. |

LDPE (Low Density Polyethylene) Process Challenges |

Major issues include raw material price volatility, supply chain interruptions, environmental concerns, and the need for constant innovation to meet sustainability regulations. |

Key Suppliers |

SABIC, ExxonMobil Chemica, and Dow Chemical Company are among the top LDPE providers, offering a diverse range of products for a variety of sectors.

|

Key Regions Covered |

Asia-Pacific and North America are key markets for LDPE adoption, with major demand in the packaging, automotive, and healthcare industries.

|

Market Drivers and Trends |

Growth is being driven by rising demand for sustainable and recyclable materials, advancements in manufacturing technology, regulatory requirements to reduce plastic waste, and developments in biodegradable LDPE goods.

|